Join devRant

Do all the things like

++ or -- rants, post your own rants, comment on others' rants and build your customized dev avatar

Sign Up

Pipeless API

From the creators of devRant, Pipeless lets you power real-time personalized recommendations and activity feeds using a simple API

Learn More

Search - "cnc mill"

-

!rant

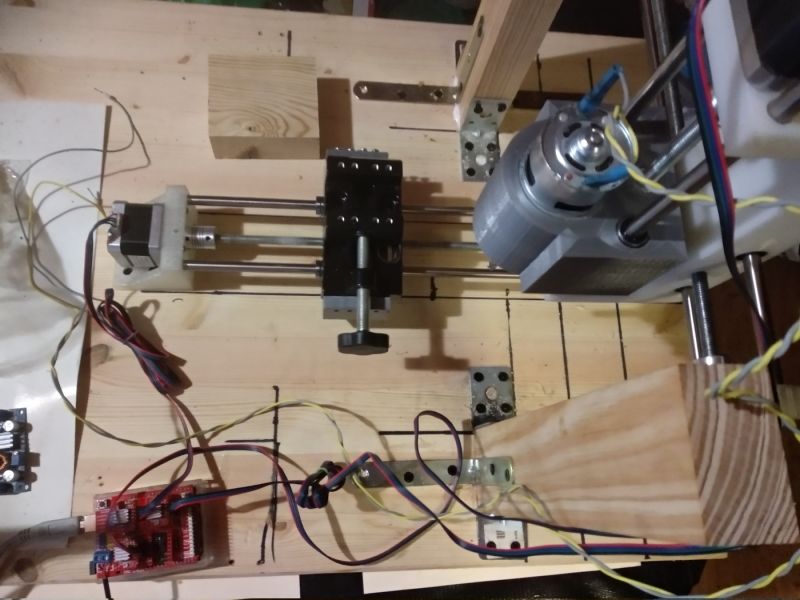

I finally did it. Finally had the energy to do... One axis for my CNC lol.

It works perfectly.

But the 28BYJ-48 are so slowwww.

- One Arduino Uno

- Two 28BYJ-48 with Uln2003A controllers (Y is already programmed)

- One joystick.

It's aliveeeee! 16

16 -

!rant

Arduino CNC

Hey guys.

Since I mostly see frameworks to use with G-Code in Arduino CNCs I'm gonna make my own framework, where you don't need to know G-Code and the code is executed by Arduino code.

The code would include a template to define steppers steps and such.

Would include a library to work with different stepper shields.

Would this interest to anyone?

I'll provide a full example with stuff to learn for any amateur working with CNCs or that want to work with one. If you're not interested, thank you for reading, you can stop here.

Ex:

X(10);

Y(-5.5);

XY(6,7.5);

Z(-10);

This framework would only use incremental coordinates and will work for basic forms, drilling and such.

<Tutorial>

Coordinates.

Coordinates can be relative/incremental or absolute.

Lets say you have a square with 10mm, (top coordinates: (X=0,Y=0) to (X=10,Y=10).

think your drawing this square.

First line:

X0, Y0

Absolute: x10,y0

Relative: X+10

Second line:

A: x10,y10

R: Y+10

Third Line (...)

Absolute is a fixed point (coordinate)

Relative is a distance to move (not a coordinate but the distance and direction)

</Tutorial>

So, to cut a square with a TR10 (end mill with radius=5, diameter=10)

<code>

// You don't place + in positive values

// The tool always cut in the direction of the tool rotation, meaning on the left of the material.

Z(10); // Security Distance

XY(-5,0); //Compensate the diameter of the tool in radius

Z(-1); // Z=0 is the top of the block to mill, in this case. Z=0 can also be in the bottom

Y(15); //Second Point

X(15); // Third Point

Y(-15); // Forth point

X-15; // Fifth Point

(repeat)

</code>

Now we have a block with 1mm depth. If you use a while or for you can repeat the sequence for x=n passages, change the value to Z for the depth and your done.30 -

So... Working alone in a hollyday, at night .

Turning mill operator.

Started working here 2 months ago.

Had to stop a machine. They like to work by brute force here, so a tool is braking on every piece I try to make...

Might just go home early.

I know what the problem is and how to solve it, but I'm new here, I'm not going to tell the engenheir how these very expensive machines should operate.

Problem is: cutting tool should cut at most 1mm per passage, they program only one passage so its cutting maybe 10mm each time.

I just had to change a few parameters in the variables for cutting depth... But they will never learn while operators solve that problem behind the boss back. So machine is resting.

Also have no more pieces to work in the other machines... They don't pay well, so 4 people left just last month for better jobs and now there isn't enough workers to keep production.

Why do people still use 1940's methods in today's companies?2